“Sir, this is Alex. Umm, there’s a whole lot of water all over that back room!”

It’s not exactly the call that you want to start your Tuesday morning with. It had been raining for several hours throughout the night, which is a good test of the integrity of a house. In this case, it forced a job that I was putting off.

We’d removed the wood burning stove from our family room and eventually moved it to our barn. However, we had left the chimney stack in place. It was fine for now (so I thought), and I’d planned to remove it, repairing the roof, when it got a bit warmer / drier.

Well, it had started leaning too much and started leaking with all of the rain and wind that we’d been having. So. Cold. In the rain. Up on the roof I went. It was too cold and wet to make any permanent repairs, so we bought a small tarp and planned to nail it down in place until it could be permanently fixed. It was a little nerve-racking being up on the wet roof. Sonya took some pictures from the ground – “likely the last pictures I’ll take of John” was what she was thinking, no doubt.

That same afternoon, we had a pow-wow with our general contractor, his planner, and the crew that would be overseeing the modifications to the back wall of the family room. You may remember that we recently discovered that most of the wall turned out to be cinder block. We didn’t really know what the extent of the work which would have to be done until this day.

The crew explained what they would have to do to complete the job. The more they talked, the lighter my wallet got. “We’ll work up a quote and get it to Bruce,” is how they left things.

Later that night, we got the news. With an explanation of what had to be done, they gave us a bill of an additional $9500. Yeesh. What could we do? So, first major setback of the project. Hopefully the last. He did tell us that they would fix the roof where the chimley was at no additional charge as a “thank you.”

The crew did get some more doors upstairs. For the bathroom door, we bought a 24″ wide door from the salvage store in hopes that it could be trimmed down some to fit the 24″ W opening. That’s exactly what Will did, and it looks great! For the girls’ room, we decided to go easy, at least for now, and buy their entryway and closet doors from a box store. We still have Seth’s room to install a door for, and that will be on us. Wish me luck on that first-time project.

Another item that the crew finished up was the stairs and the banister. As you can see, they did a phenomenal job bringing our vision to life. Sonya had run across an idea for a small shelf set to better utilize the space under the stairs. Alex Jr. did a great job there. The pictures I took were before they were done, but you get the idea.

Friday evening and Saturday were times for us to get some things done. Eli and I had installed headers over the entries from the kitchen to the dining room and family room. Friday night, I spent a little time putting up drywall on the headers. A drywaller, I am not. But it was good practice, at least. Hopefully, whoever ends up finishing it won’t be too upset with me. It was all in preparation to install the ceiling of the kitchen.

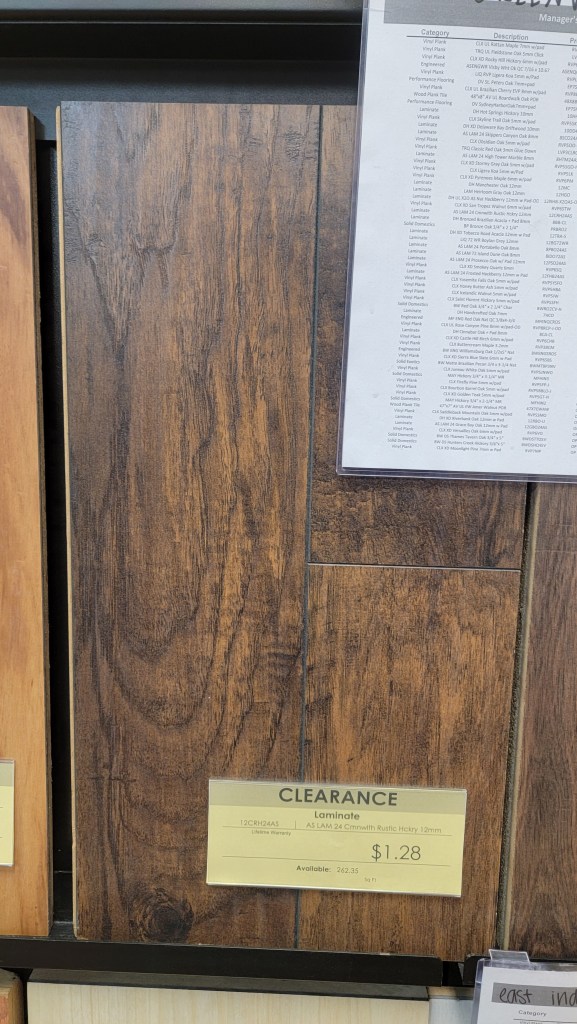

We’d been giving the flooring some more thought lately and had gotten some recommendations for where to go for the hardwood flooring that we wanted to install on the firat floor. So far, we’d been to the box stores to look and had been largely entertaining the idea of installing it ourselves. We weren’t entirely happy with the price of hardwood flooring, so we decided to do our due diligence and shop around. We quickly cam to the realization that 1, we’d probably already found the lowest price, 2, hardwood floors were going to just be expensive, and 3, it probably wasn’t going to be a good idea for us to try to install them ourselves.

So, have it done right, have it done quick, have it done cheap – pick two. We decided that with as visible as the flooring would be, we wanted to have it professionally installed. We probably could do it ourselves, but it would take us longer, jeopardizing our aggressive move in date, and likely with mistakes. ✅️ Have it done right. ✅️ Have it done quick.

Something else that we considered was another choice in the type of flooring. We had hardwood floors at our house on Orchard Lane and loved them. We really didn’t want to stray too far from that. We took a closer look at engineered hardwood flooring. Benefits were that it would be less expensive for materials, potentially less expensive to install (we don’t know for sure yet), and they seemed to be overall less maintenance and even more longevity than hardwood floors.

We got some samples, and we have an installation guy coming out next Saturday to go over some options. ❓️Have it done cheap(er)? We’ll see.

Saturday was kind of a fun day (I thought, anyway). We’ve heard that a true test of a marriage is hanging wallpaper together. We’d hung wallpaper years ago with no significant marital problems arising. Now, we were ceetainly in next-level marriage stuff. We hung drywall together last weekend, which I suppose is another one of those marriage tests. Saturday, it was installing shiplap on the ceiling of the kitchen.

First, Sonya and Meagan worked on putting up the insulation while I worked on the headers drywall Friday night.

Second, just out of curiosity, we hung some lights to get an idea of what the kitchen and dining room would look like. Something told me that the single light in the kitchen wouldn’t be enough. Turns out that I was right for the first time this year+2. Luckily, we had 4 canned lights left over from the family room, so we installed those as well, which really lit up the kitchen.

With those two items out of the way, and some additional removal of some old drywall, it was time to tackle this shiplap. Overall, it went up fairly easy. With remodeling this older house, we ran into the same issue as with the drywall installation in the family room – the joists were uneven. So we were nervous about that. Turns out that the shiplap was great for compensating for the joist height differences (which were only slight in the kitchen). Cutting the boards to length was easy. The biggest challenge was cutting holes for the canned lights. Turned out that a large Speedway Big Gulp cup lid was the perfect template. We got about a third of the ceiling completed by Saturday night.